|

|

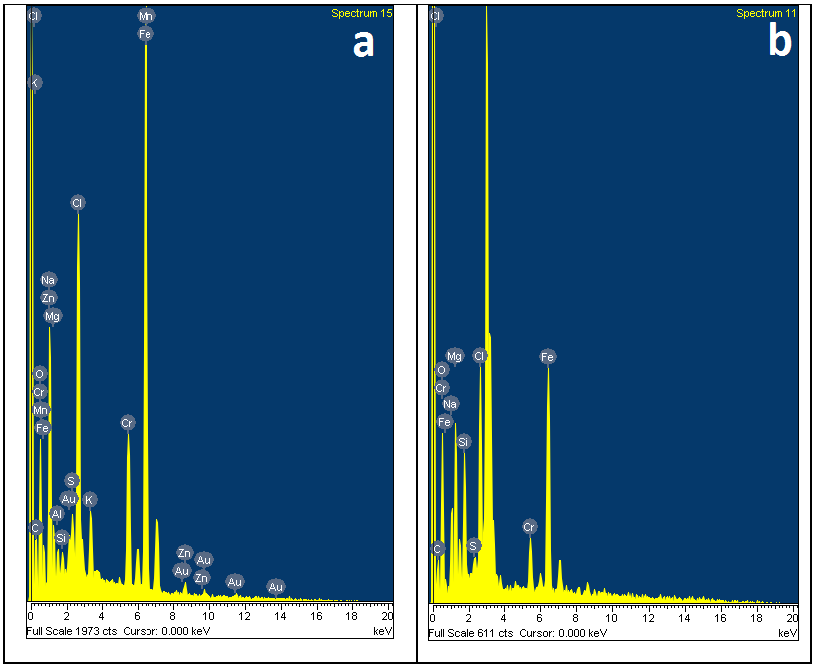

The blades of the last stage of steam turbines are subject to corrosive environment and cyclic load, which could lead to failures due to crack propagation and corrosion. Some turbine blades are made of materials like stainless steel AISI-410. In this paper the effect of temperature on corrosion crack propagation produced in a stainless steel AISI-410 type was studied. The cracked specimens were exposed in seawater during 5 days at two temperatures (25 °C and 90 °C) in static conditions. The corrosion was studied using the electrochemical noise technique (EN) and potentiodynamic polarization curves (PC). The electrochemical noise time series were used to analyze the changes in corrosion activity for AISI-410 under the mentioned experimental conditions determining the type and corrosion rate. The results showed that cracks were grown when exposed in seawater, especially at the higher temperature. Physical characterization obtained from SEM showed a great amount of corrosion products emerging from the cracks, observing a mixed corrosion type around the cracks: uniform and pitting. From the results, it is deduced that this corrosion attack may influence crevice corrosion, which eventually leads to stress corrosion cracking and corrosion fatigue.

Keywords: Corrosion, electrochemical noise, cracks, pitting, AISI-410.

|

|

|