|

|

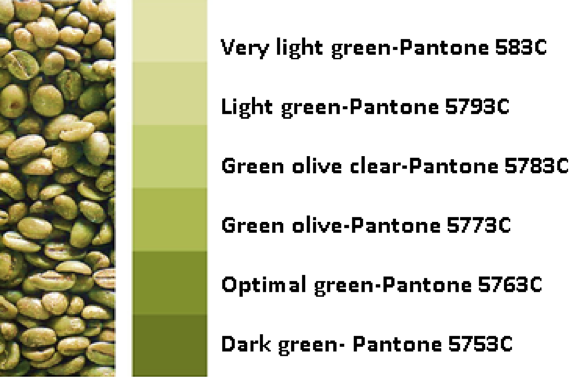

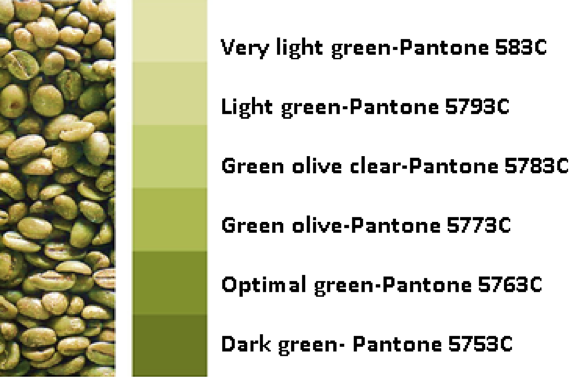

Drying is one of the most important operations in the coffee processing industry, which consists of removing some water contained in the grain, from 55% moisture content to 10 or 12%. In the present paper, an industrial dryer of vibrofluidized bed of coffee beans (Coffee arábica L.) was optimized, which until the year 2017 presented losses in the drying process about 19% of total coffee beans treated. An analysis of the hydrodynamic and vibrational operation parameters of the dryer was carried out, as well as considerations on the physical properties and drying kinetics of coffee beans. The process operated continuously with a mass flow of coffee beans () of 3800 kg/h, an initial bed height () of 5 cm and a total drying time () of 1.3 h. The optimum temperature resulted of 225 ° C, which allowed to obtain a very light green color, named in the color scale as Pantone 5803C, which denotes a high quality for the type of coffee bean processed in the industry, with a final humidity of and maintaining a drying speed of .

Keywords: vibrofluidized dryer, optimization , drying kinetics, temperature.

|

|

|