|

|

Sugar cane molasses are, locally, the main raw material in bioethanol production process, which is affected by hydrocolloids presence, mainly dextran, raising fluids viscosity, generating clogging and embedding problems in equipment.

The main goal of this study is to degrade those compounds, increasing the bioethanol production process efficiency by reducing sludge generation and its embedding in the first distillation column inner wall.

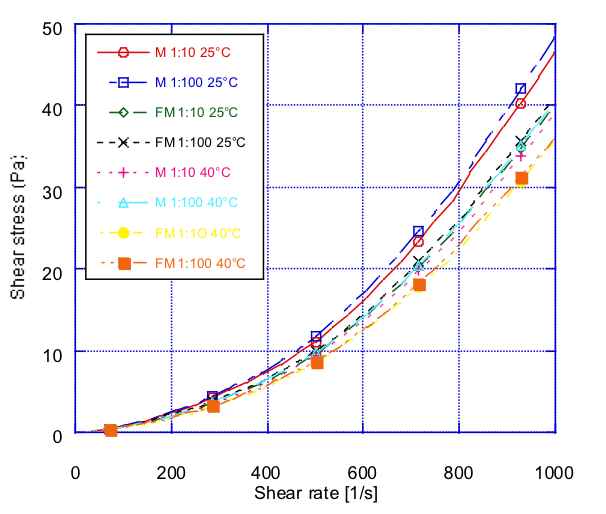

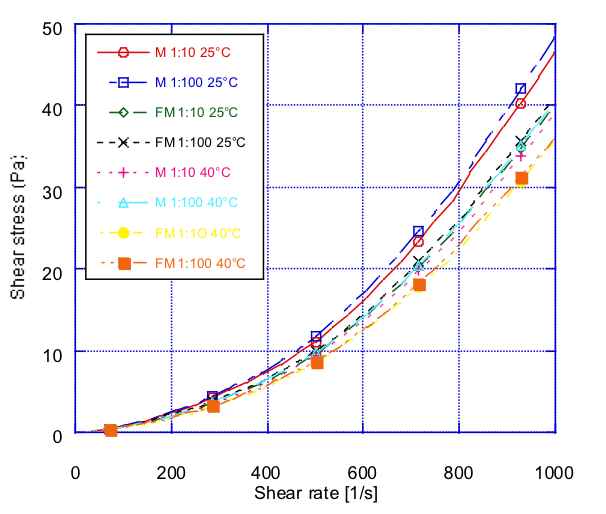

Physicochemical, microbiological and rheological characterization was carried out at mash and fermented mash samples. Dextran degradation was accomplish by enzymatic hydrolysis in presence of dextranase enzyme, evaluating the enzyme-substrate relation, substrate type, and temperature effects, applying a factorial design.

It was found that Leuconostoc mesenteroides bacteria does exists in the fermented mash. Both mash and fermented mash showed a non-Newtonian behavior, with a flow behavior index greater than one (n > 1), fitting well to Herschel-Bulkley model. The highest enzyme activity was observed at 40°C, obtaining a lower viscous product (0.017 Pa s, 28.978% of reduction) and a lower dextran concentration product (173.220 ppm, 64.767% of reduction).

Keywords: dextran, dextranase, molasses, mash, bioethanol, rheology.

|

|

|