|

|

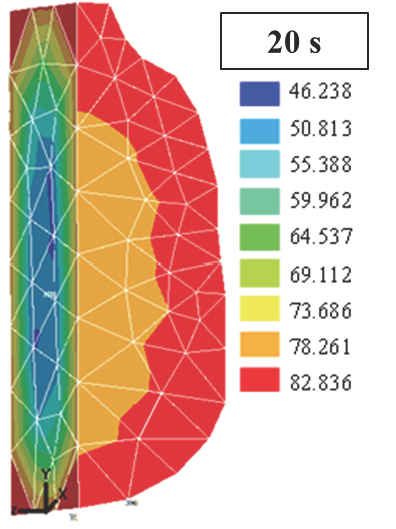

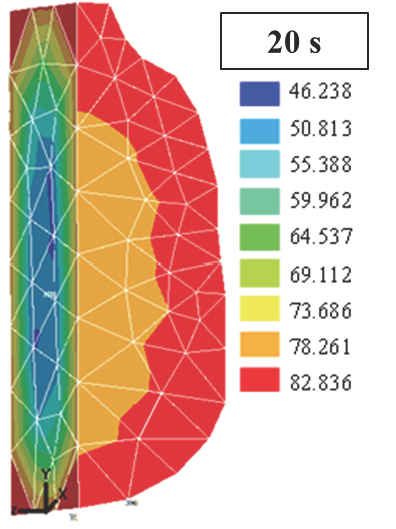

Maize nixtamalization is an alkaline cooking process that yields several food products. One of the critical parameters which are traditionally monitored in the process is temperature; however, to date the measurement of this variable has not been carried out inside the corn kernel itself. In this study, heat transfer inside a corn kernel during the nixtamalization process was simulated by means of finite element analysis (FEA) in a tridimensional (3D) model. In addition, thermophysical properties of corn kernel [thermal conductivity (k), specific heat capacity (Cp) and bulk density (ρb)] were determined as a function of temperature (25, 50 and 75 °C). The magnitudes of the thermophysical properties increased with temperature and the convective heat transfer coefficient (h) was computed as 2143 ± 407 W/m2·K (NBi =0.0094). Also, the simulation model was good (R2adj > 0.99) and predictions showed that the corn kernel’s surface was rapidly heated and the alkaline solution’s temperature (85 °C) at corn kernel’s center was achieved at 80 s of heating. Furthermore, some predictions in the anatomical parts of the corn kernel were performed. This study contributes to the understanding and improvement of the optimal conditions of the nixtamalization process which allows saving energy, having economic rewards and obtaining high quality nixtamalized products.

Keywords: nixtamalization, corn kernel, thermophysical properties, heat transfer simulation, finite element analysis.

|

|

|