|

|

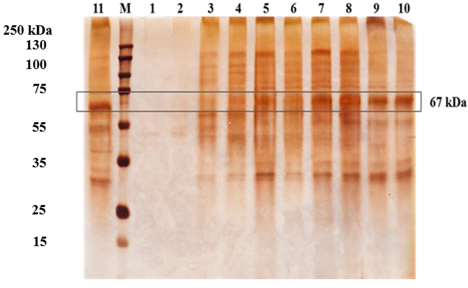

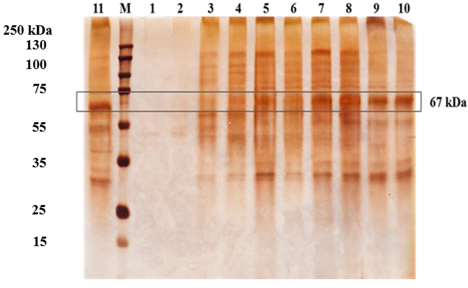

It was developed a fed-batch bioprocess to produce a recombinant vaccine against Entamoeba histolytica under operational conditions attainable to large scale bioprocesses. We have produced this recombinant protein in shake flask and stirred tank bioreactor. Initial results in shake flask cultures under different methanol concentration of 0.5, 1.5 and 3% (v/v) produced extracellular protein at quantities of 10, 22 and 33 μg/mL, respectively. Then a scale-up process was performed from shake flask to fermenter by keeping similar volumetric power supply (P/V). The operational conditions were set up in fermenter as those used at commercial scale and supply of pure oxygen was avoided to keep the scalability of the bioprocess. After the scale-up process, the production of the recombinant protein reached 0.43 mg/mL, an improvement in production of 12 times, although the methanol and oxygen limited conditions observed. Maximum volumetric productivity of 3.75 mg/L h was achieved in fermenter cultures against 263.75 µg/L h reached in shake flask. Besides the limited conditions in methanol and oxygen, the yields obtained from the bioprocess were comparable to those observed in Mut+ strains previously reported, then saturated methanol conditions are not necessary to compensate limited oxygen conditions.

Keywords: Methanol limited feed, recombinant vaccine, alcohol oxidase promoter, stirred tank bioreactor, shake flask.

|

|

|