Revista Mexicana de Ingeniería Química, Vol. 19, No. 3 (2020), Proc1082

Automation of the successive ionic layer adsorption and reaction -SILAR- process

|

J.S. Valdez-Martínez, M.A. Meneses-Arcos, M. Calixto-Rodriguez, J.Y. Rumbo-Morales, M.A. Beltran-Escobar, J. Villanueva-Tavira, E. Sarmiento-Bustos

https://doi.org/10.24275/rmiq/Proc1082

Abstract

|

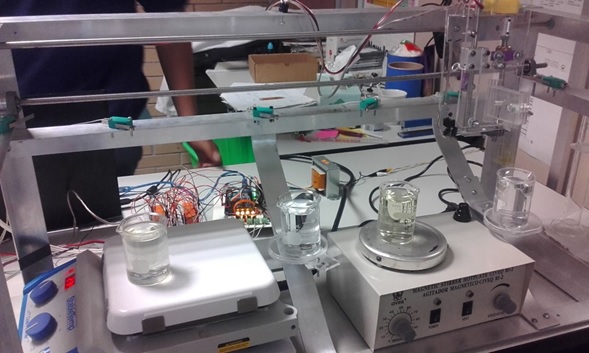

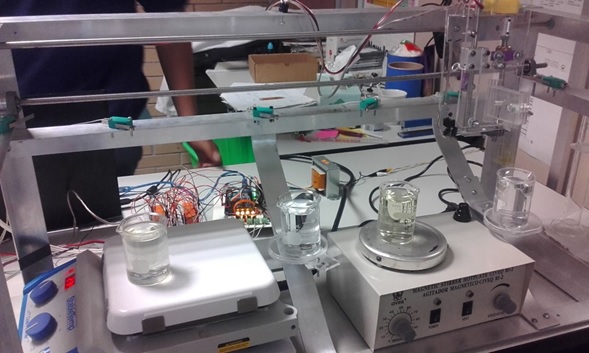

|

An electromechanical system controlled by a graphic interface developed in a JAVA programming environment was designed and developed, which allows the control of the growth parameters of thin semiconductor films of copper oxides on glass substrates obtained by the SILAR technique. The parameters that can be controlled through the graphical interface are: time, immersion sequence in the solutions and number of cycles. A low-cost microcontroller was used that allowed adapting an electromechanical system with DC motors that locates the substrate holder in the respective chemical solutions The information of the control parameters and the progress of the process can be visualized in any computer system where the developed program be executed. The results obtained show that the SILAR automated system allows obtaining homogeneous thin film deposits. The film thicknesses are controlled by the number of cycles programmed in the SILAR process.

Keywords: SILAR, chemical bath deposition, thin films, semiconductor films, automation.

|

|

|