|

|

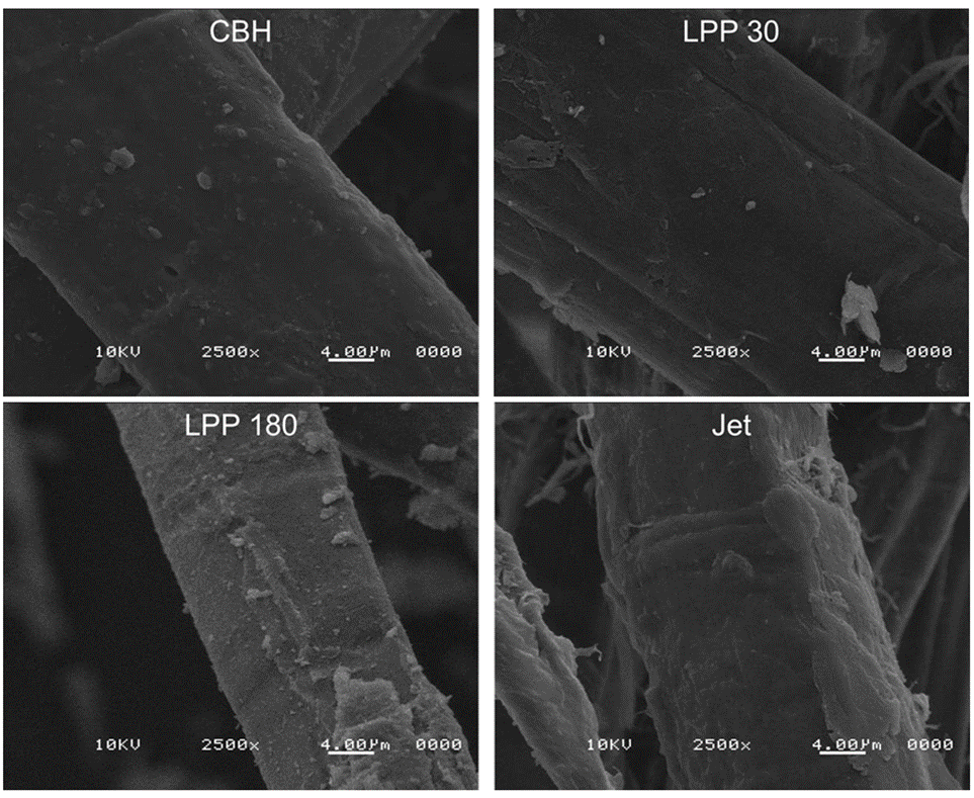

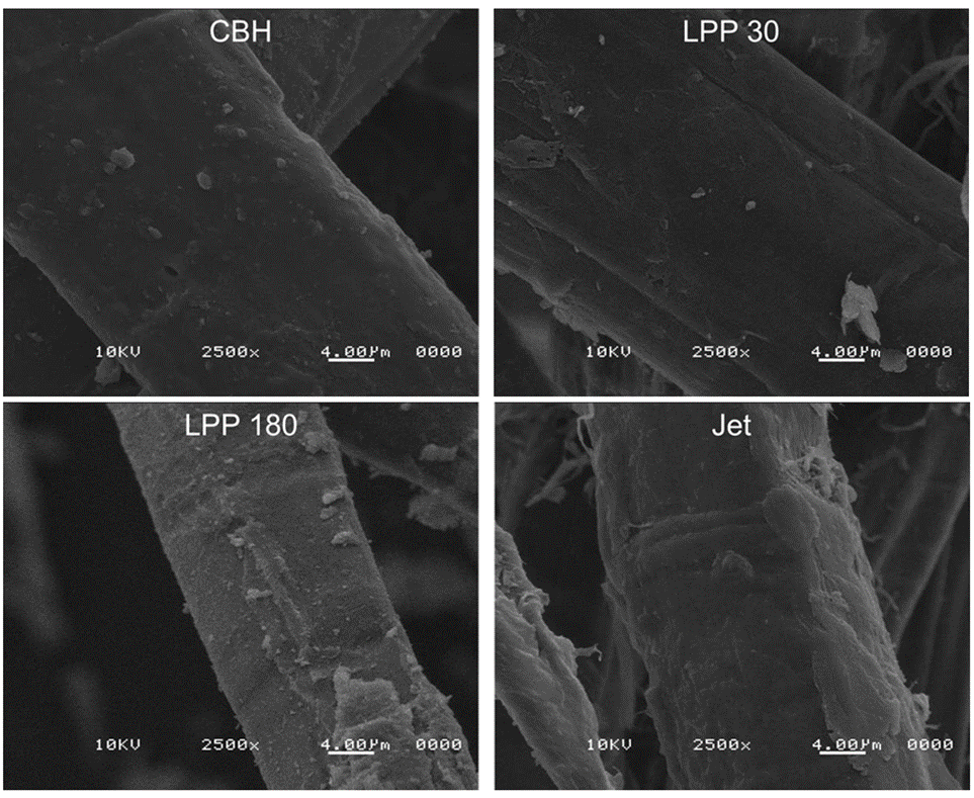

The use of cold plasma surface modification techniques has lately gained increasing interest as a complementary green option to modify the thermal stability of bio-based fibers, and thus make them more suitable for polymer reinforcing applications. In this study, commercial bleached hemp (CBH) fibers were modified using low-pressure rotatory plasma (LPRP) and atmospheric-pressure plasma jet (APPJ) devices to be further characterized by Fourier transform infrared spectroscopy―attenuated total reflectance mode (FTIR-ATR), X-ray diffraction (XRD), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). FTIR analysis evidenced the oxidation and crosslinking of cellulose chains. XRD analysis revealed a slight increase in interplanar distances of cellulose chains, that was attributed to the interchain insertion of functional groups. SEM images displayed much rougher surfaces for the treated CBH fibers than for the untreated one. TGA showed that LPRP (30 min treatment) and APPJ increased the thermal resistance of CBH fibers in 30 and 61 °C, respectively. For LPRP, a longer exposition time (180 min) provoked significant eroding without improving the thermal resistance. Finally, the cold plasma surface modification of bleached hemp fibers may well assist with the mechanical interlocking and thermal resistance (during processing) when applied in polymer reinforcing.

Keywords: plasma jet, low-pressure plasma, hemp fiber, thermal stability, cellulose.

|

|

|