|

|

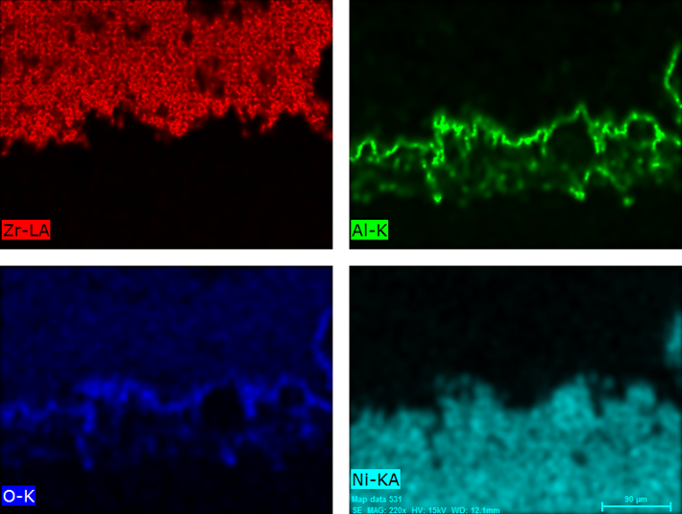

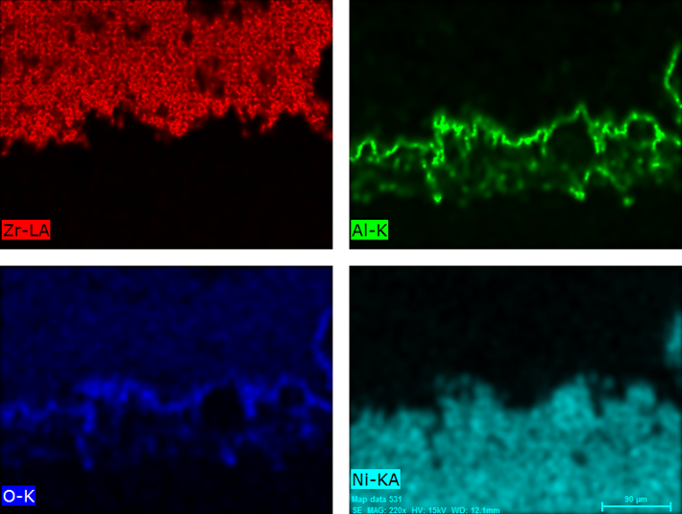

Ceramic coatings of zirconium oxide (ZrO2) were prepared and stabilized with yttrium oxide (7-8 wt% Y2O3) by plasma-aided thermal projection (APS), at different injection distance and carrier gas flow conditions. Ageing thermal treatments were performed to know the corresponding effects on the quality and performance of the thermal barrier. Determination of layer thickness of the thermal barrier, evolution of the thermally grown oxide (TGO) layer and the evaluation of the mechanical properties through nanoindentation was carried out by the micro-structural study. Results shown out that the effect of the projection distance is not significant. However, a significant effect of the gas flow, namely, the lower the flow is, the higher the thickness of the ceramic layer. Apparently, the layers coatings micro-structure is not significantly altered (the form of the splats) due to the increase in the treatment time, but the distribution of the defects and the exogenous particles (pollutants) presented clear shifts. Consequently, a decrease for the values of the mechanical properties of the layers which produce the thermal barrier was observed; also, thickness of the TGO layer was increased because of the thermal treatment time. During undertaken studies, the TGO layer never exceed the critical limit.

Keywords: manufacturing parameters, quality, ceramic coating.

|

|

|