|

|

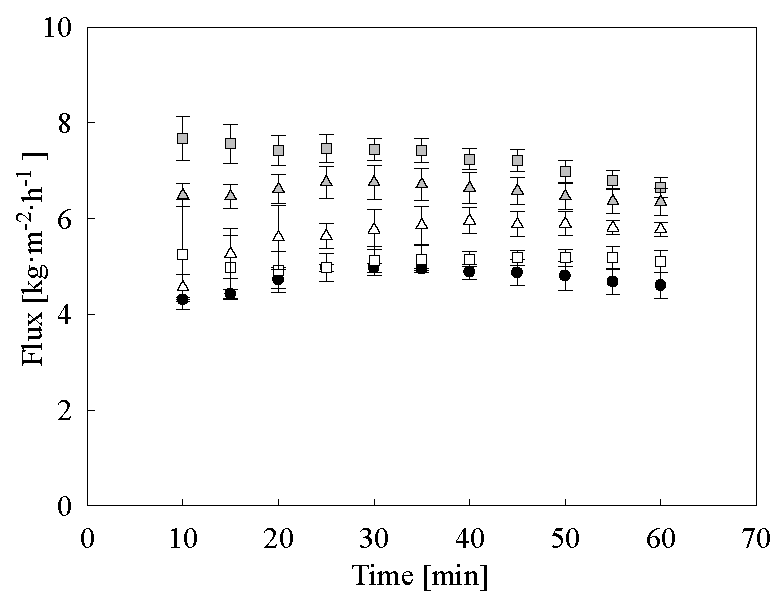

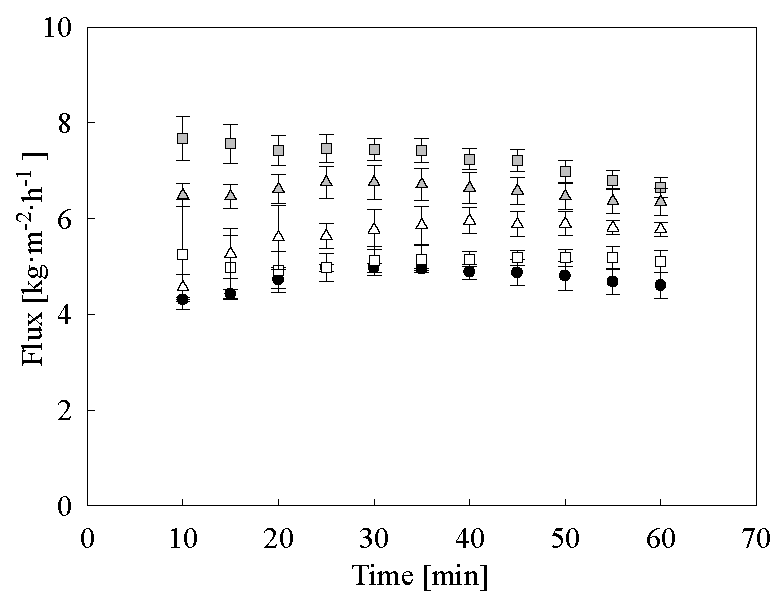

The effect of hydrodynamic conditions (feed and permeate flow rates) and the action of six different types of antiscalants on desalination of seawater from the Gulf of Mexico by direct contact membrane distillation (DCMD) was studied. The effect of feed temperature during the DCMD process was also evaluated on performance of two microfiltration membranes (0.5 µm) having different thickness (300 and 250 µm). Results showed more than 100 % increments on water vapor flux by raising feed temperature from 50 to 70 oC and feed flow rates up to 7 L·min-1. No significant effect on process performance was determined by raising permeate flow rates in the range tested. Choosing the type and concentration of antiscalants is critical during seawater desalination by DCMD. Performance of this process increased by up to 49.2 % during desalination of real seawater by adding the KMRO S-516 antiscalant designed to disperse iron, silica and calcium carbonate salts. During DCMD no important water vapor flux decay and no increase on conductivity of the distillate was observed by antiscalants’ dosage. In addition, scanning electron microscopy (SEM) from the membrane surface after DCMD desalination of seawater treated with the KMRO S-516 antiscalant confirmed the absence of scaling.

Keywords: Antiscalant, seawater, desalination, operation conditions, direct contact membrane distillation.

|

|

|