|

|

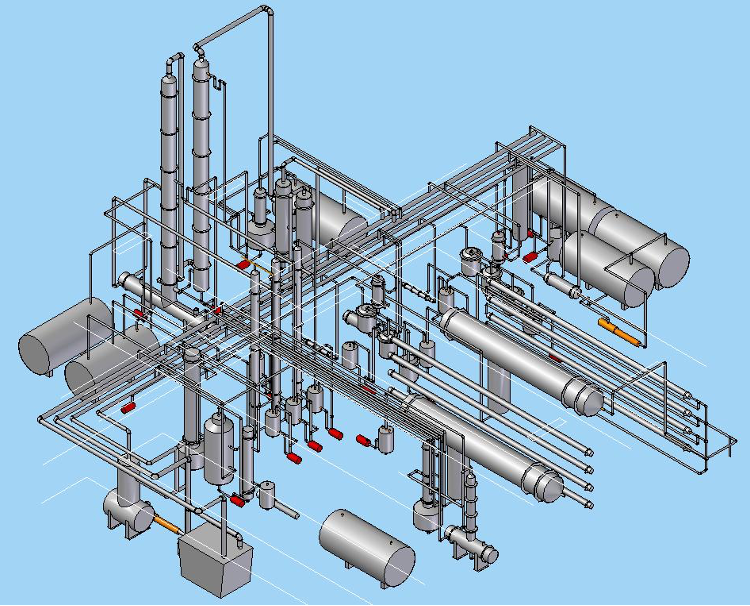

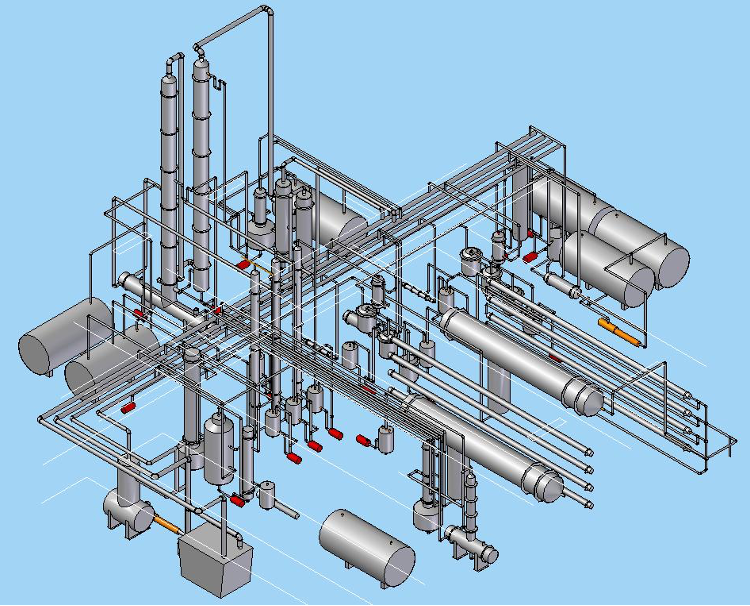

In this paper, the evaluation and implementation of a control grid for a continuous biodiesel production plant was carried out using a layout that allows the use of ethyl alcohol (C2H5OH) and methyl alcohol (CH3OH), and a capacity of 100 L/h. First, the production system was divided into 8 subsystems, in order to identify and detail all the sub-processes that happen in the plant during the production of biodiesel. Then, it was developed careful studies of the systems and identification of the processing steps that demand a greater need for automation, using applied control strategies according to the specific need of each one, such as: feedback, on-off, ratio and proportion, split rang, and cascade. Thus, utilizing PFD (Process Flow Diagram) and P & ID (Piping and Instrumentation Diagram), it was possible to obtain a control loop capable of integrating the entire plant, aiming at greater stability of all process variables, which in turn result in a better functioning of the plant, as well as a final product capable of meeting the most varied quality standards, from different raw materials.

Keywords: Continuous unit, biodiesel, industrial automation, control strategies.

|

|

|