|

|

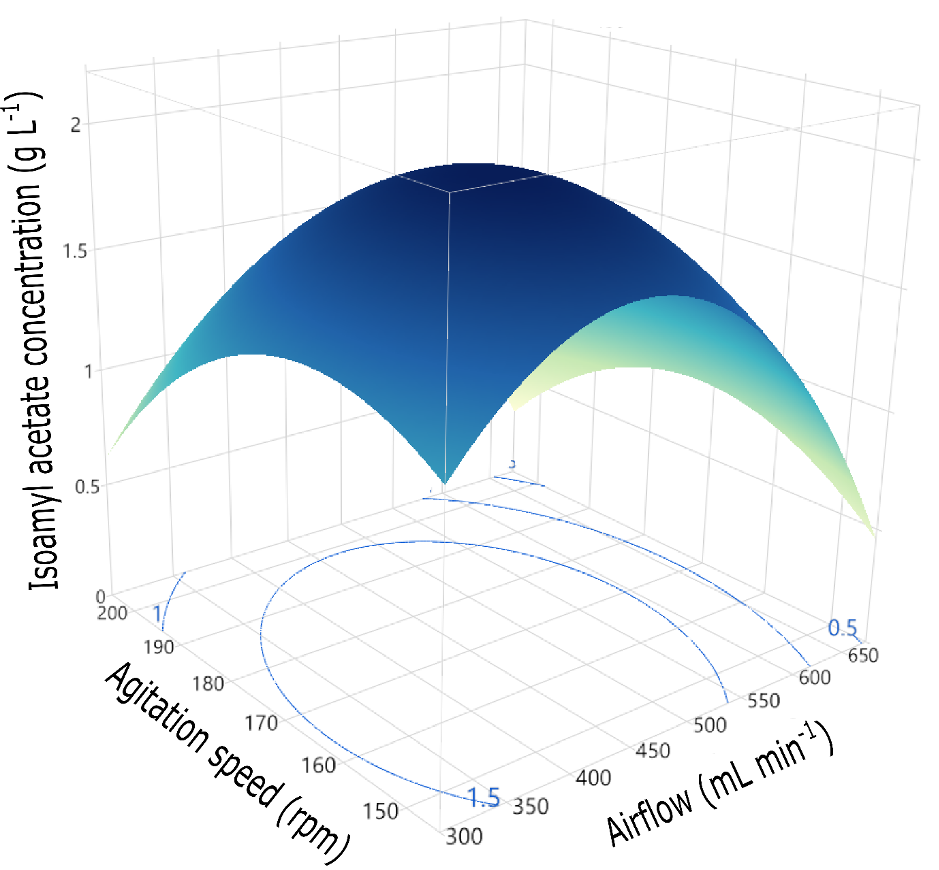

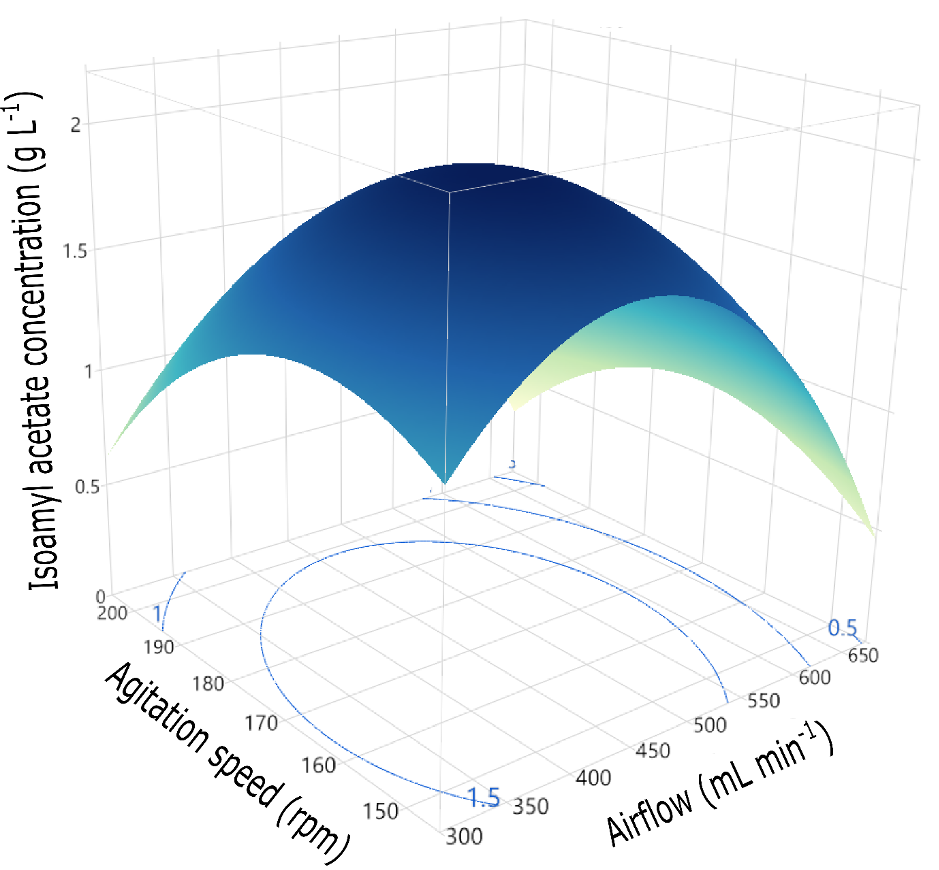

Microbial production of aroma compounds is a promising alternative to extracting plants or chemical synthesis. The yeast Pichia fermentans ITD-00165 has demonstrated a high potential to produce isoamyl acetate. The yeast was cultured in a bioreactor on a chemically defined medium to evaluate the influence of airflow (0.5, 0.75, and 1.0 vvm) and agitation speed (150, 175, and 200 rpm) on the isoamyl acetate production. Isoamyl acetate was retained using an in situ entrapping system, which was obtained, adding a cap of n-decane in a ratio of 80:20 (medium:decane). This work demonstrated the relevance of well-controlled aeration to enhance isoamyl acetate production using isoamyl alcohol as a precursor. Culture operating near to 0.71 vvm and 168 rpm (kLa = 0.16 min-1) achieved production of 2.14 g L-1, which means an almost 2.5-fold increase in respect to the higher value previously reported. On the other hand, the minimum production occurred at the best aeration conditions (kLa = 0.22 min-1), meaning that excessive aeration could negatively affect the aroma production. Nevertheless, it appears that the concomitant ethanol production negatively affects aroma production.

Keywords: Non-Saccharomyces yeasts, banana aroma, aeration, extractive fermentation.

|

|

|