Revista Mexicana de Ingeniería Química, Vol. 21, No. 1 (2022), Bio2654

Isoamyl acetate production during continuous culture of Pichia fermentans

|

A. Paredes-Ortíz, T.G. Olvera-Martínez, J.B. Páez-Lerma, J.A. Rojas-Contreras, M.R. Moreno-Jiménez, C. Aguilar, N.O. Soto-Cruz

https://doi.org/10.24275/rmiq/Bio2654

Abstract

|

|

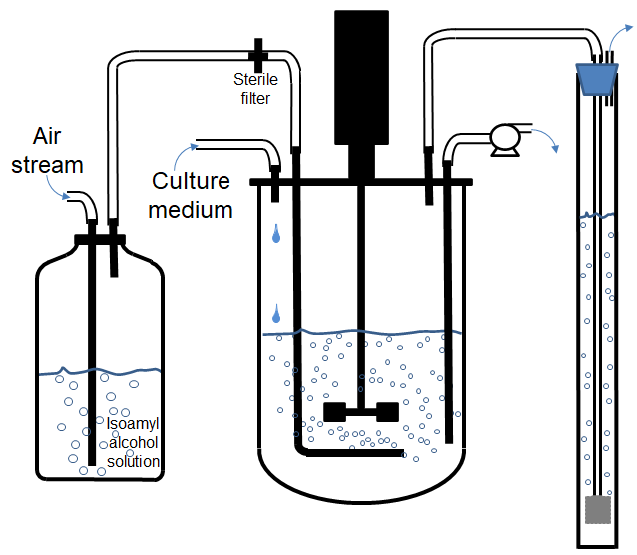

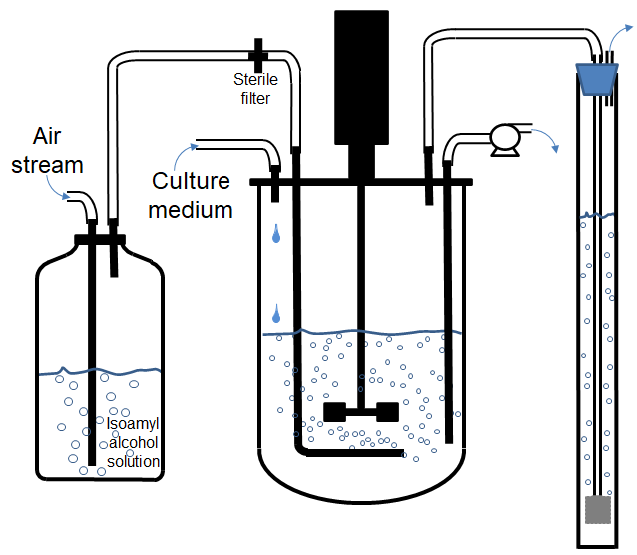

The yeast Pichia fermentans ITD-00165 has demonstrated high potential to produce isoamyl acetate in batch culture. This work aimed to attempt isoamyl acetate production in continuous culture. A bioreactor containing a chemically defined medium was used to develop continuous cultures at three dilution rates (0.25, 0.30 and 0.35 h-1). Isoamyl acetate concentration was measured using an entrapping system based on a bubbling column with n-decane. Results demonstrate that the entrapping system showed a linear correlation between the isoamyl acetate concentration into the culture medium and the absorption rate into the column. Airstream for oxygen supply was successfully used to continuously feed isoamyl alcohol to the culture to diminish the inhibitory effect of the precursor. Finally, it was demonstrated that the continuous culture growing cells assimilated the precursor to reach a steady-state isoamyl acetate production of 0.144 mg L-1.

Keywords: Aroma compound, Isoamyl alcohol, Non-Saccharomyces yeasts, banana aroma, Bubbling column.

|

|

|