|

|

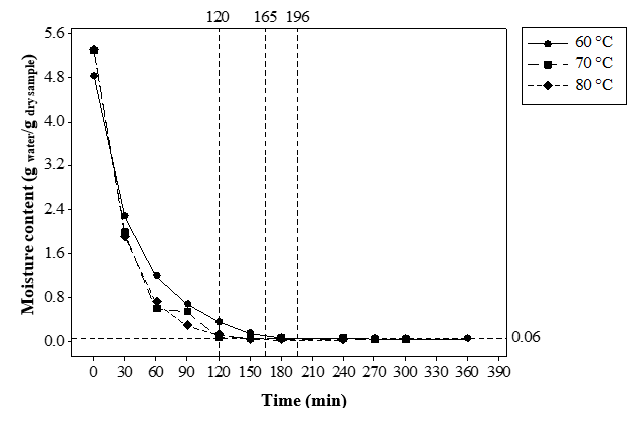

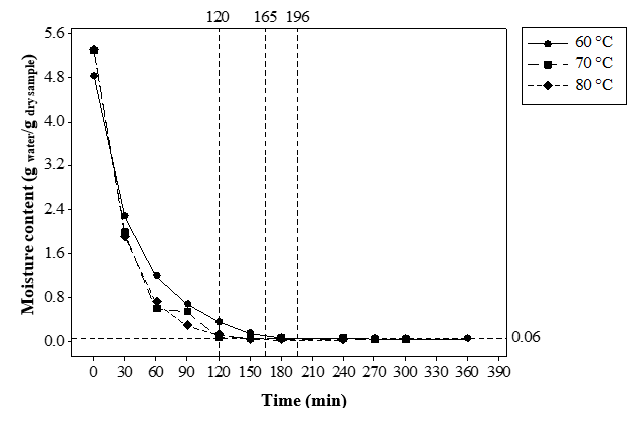

In this study, the influence of the drying method (lyophilization and convection) on the antioxidant properties of the by-product of xoconostle (Opuntia matudae) was evaluated. The analysis of convection drying results indicated that the drying took place during the period of decreasing speed, besides the drying speed was influenced by the rise in temperature, reaching the target moisture content (0.06 gwater/gdry~sample) in shorter processing times as the temperature increased (60 °C-195 min; 70 °C-165 min; 80 °C-120 min). The effective diffusivity coefficients (Def) ranged between 4.788 E-10 -8.109 E-10 m2/s for the evaluated temperatures. Drying by lyophilization and by convection at 60 °C were ideal for the preservation of antioxidant capacity, however, considering the cost-benefit ratio, convective drying at 60 °C is more favorable for its use on the xoconostle by-products since they showed to maintain phenolic compounds (72.56 $\pm$ 0.06 mg GAE/100 g) and antioxidant capacity determined by ABTS and DPPH (7.63 ± 0.96 TEAC/gsample, 88.07 $\pm$ 0.38 % DPPH inhibition). Therefore, powdered by-products can be incorporated as functional additives.

Keywords: betalain, total phenols, antioxidant capacity, drying kinetics, flow properties.

|

|

|