- Andreou, V., Thanou, I., Giannoglou, M., Giannakourou, M.C., & Katsaros, G. (2021). Dried figs quality improvement and process energy savings by combinatory application of osmotic pretreatment and conventional air drying. Foods 10(8), 18-46. doi:10.3390/foods10081846

- AOAC (1997). Official methods of the Association of Official Methods of Analysis. 16th edition. Arlington.

- Assis, F., Morais, R., & Morais, A. (2017). Osmotic dehydration with sorbitol combined with hot air convective drying of apple cubes. Journal of Food Science and Technology 54(10), 3152-3160. doi:10.1007/s13197-017-2751-0

- Bai, X., Campagnoli, M., Butot, S., Putallaz, T., Michot, L., & Zuber, S. (2020). Inactivation by osmotic dehydration and air drying of Salmonella, Shiga toxin-producing Escherichia coli, Listeria monocytogenes, hepatitis A virus and selected surrogates on blueberries. International Journal of Food Microbiology 320, 10852. doi: 10.1016/j.ijfoodmicro.2020.108522

- Bantle, M., & Eikevik, T. (2014) A study of the energy efficiency of convective drying systems assisted by ultrasound in the production of clipfish. Journal of Clean Production 65, 217-223. doi: 10.1016/j.jclepro.2013.07.016

- Bchir, B., Sebii, H., Danthine, S., Blecker, C., Besbes, S., Attia H., & Bouaziz, M. (2021). Efficiency of osmotic dehydration of pomegranate seeds in polyols solutions using response surface methodology. Horticulturae 7(9), 268. doi:10.3390/horticulturae7090268

- Bera, D., & Roy, L. (2015). Osmotic dehydration of litchi using sucrose solution: effect of mass transfer. Journal of Food Process Technology 6(7), 62-69. DOI: 10.4172/2157-7110.1000462

- Borja-Málaga, M., Jiménez-Ochoa, A., Medina-de Miranda, E., Escobedo-Vargas, F. (2022). Effect of drying on the extraction yield of Luma chequen (Molina) A. Gray essential oil. Revista Mexicana de Ingeniería Química 21(2), Proc2623. https://doi.org/10.24275/rmiq/Proc2623

- Bussolo de Souza, C., Melliana, J., Isay, S., Schols, H., & Venema, K. (2018). Characterization and in vitro digestibility of by-products from Brazilian food industry: Cassava bagasse, orange bagasse and passion fruit peel. Bioactive Carbohydrates and Dietary Fibre 16, 90-99. doi: 10.1016/j.bcdf.2018.08.001

- Çağlayan, D., & Barutçu, I. (2018). Effects of ultrasound-assisted osmotic dehydration as a pretreatment and finish drying methods on the quality of pumpkin slices. Journal of Food Process Preservation 42(9), e13679. doi:10.1111/jfpp.13679

- Chavan, U., & Amarowicz, R. (2012). Osmotic dehydration process for preservation of fruits and vegetables. Journal of Food Research 1(2). doi:10.5539/jfr. v1n2p202

- CIAT. (2022). In Colombia, the first digital catalog of cassava varieties from Cauca is launched. International Center for Tropical Agriculture. Available at: https://www.agronet.gov.co/Noticias/Paginas/En-Colombia,-se-lanza-el-primer-cat%C3%A1logo-digital-de-variedades-de-yuca-del-Cauca.aspx. Accessed April 4, 2022

- Contreras, K., Arrieta, P., Salcedo, J., & Cervera, M. (2016). Cassava bran dehydration by combined methods. Vitae 23, (Supl.1), s231-s235. Accessed: September 6, 2022. https://www.proquest.com/docview/1783660297?pq-origsite=gscholar&fromopenview=true

- Da Costa Ribeiro, A., Aguiar-Oliveira, E., & Maldonado, R. (2016). Optimization of osmotic dehydration of pear followed by conventional drying and their sensory quality. LWT - Food Science and Technology 72, 407-415. doi: 10.1016/j.lwt.2016.04.062

- Dermesonlouoglou, E., Chalkia, A., & Taoukis, P. (2018). Application of osmotic dehydration to improve the quality of dried goji berry. Journal of Food Engineering 232, 36-43. doi: 10.1016/j.jfoodeng.2018.03.012

- Deshmukh, S., Gabhane, S., & Deshmukh, D. (2021). Osmotic dehydration of carrot strips and modelling. Journal of Physics Conference Series 1913(1), 012093. doi:10.1088/1742-6596/1913/1/012093

- Domínguez‐Niño, A., Salgado‐Sandoval, O., López‐Vidaña, E., César‐Munguía, A., Pilatowsky‐Figueroa, I., & García‐Valladares, O. (2021). Influence of process variables on the drying kinetics and color properties of pear slices (Pyrus communis). Color Research and Applications 46(5), 1128-1141. doi:10.1002/col.22625

- Escaramboni, B., Fernández Núñez, E, Carvalho, A., & de Oliva Neto, P. (2018). Ethanol biosynthesis by fast hydrolysis of cassava bagasse using fungal amylases produced in optimized conditions. Industrial Crops Production 112, 368-377. doi: 10.1016/j.indcrop.2017.12.004

- Eyerson, K., & Ankrah, E. (1975). Composition of Foods Commonly Used in Ghana. Food research institute-Ghana.

- Feng, Y., Yu, X., Yagoub, A. E. A., et al. (2019). Vacuum pretreatment coupled to ultrasound assisted osmotic dehydration as a novel method for garlic slices dehydration. Ultrasonics Sonochemistry 50, 363-372. doi:10.1016/j.ultsonch.2018.09.038

- Ferreira, J. P. L., Castro, D. S. de, Moreira, I. dos S., Silva, W. P. da, Figueirêdo, R. M. F. de, & Queiroz, A. J. de M. (2020). Convective drying kinetics of osmotically pretreated papaya cubes. Revista Brasileira de Engenharia Agrícola e Ambiental 24(3), 200-208. doi:10.1590/1807-1929/agriambi.v24n3p200-208

- Fiorda, F. A., Soares, M. S., da Silva, F. A., de Moura, C. M. A., & Grossmann, M. V. E. (2015). Physical quality of snacks and technological properties of pre-gelatinized flours formulated with cassava starch and dehydrated cassava bagasse as a function of extrusion variables. LWT - Food Science and Technology 62(2), 1112-1119. doi:10.1016/j.lwt.2015.02.030

- Florencia, V., López, O. V., & García, M. A. (2020). Exploitation of by-products from cassava and ahipa starch extraction as filler of thermoplastic corn starch. Composites Part B: Engineering 182, 107653. doi:10.1016/j.compositesb.2019.107653

- García, C. C., Mauro, M. A., & Kimura, M. (2007). Kinetics of osmotic dehydration and air-drying of pumpkin. Journal of Food Engineering 82, 284-291.

- García, M., Salcedo, J., & Hernandez, E. (2016). Viscoelasticity in bakery doughs formulated with wheat flour and cassava bran. Vitae 23, 250-254.

- García Mahecha, M., Cortes Rodríguez, M., & Sandoval E.R. (2010). Evaluation of parsley drying applying osmotic dehydration techniques as pretreatment. Revista Facultad Nacional de Agronomía Medellín 63(2), 5693-5705.

- García Paternina, M., Cardona Arbeláez, A. A., & García Mogollón, C. A. (2020). Diagnosis of the management of cassava bran in the department of Sucre. In: Innovation in the Caribbean Region of Colombia: Theoretical Contributions and Good Practices. Editorial CECAR. doi:10.21892/9789585547858.9

- García-Noguera, J., Oliveira, F. I. P., Gallão, M. I., Weller, C. L., Rodrigues, S., & Fernandes, F. A. N. (2010). Ultrasound-assisted osmotic dehydration of strawberries: Effect of pretreatment time and ultrasonic frequency. Drying Technology 28(2), 294-303. doi:10.1080/07373930903530402

- Geankoplis, C. J. (1998). Transport Processes and Unit Operations (3rd ed.). Continental. P.617.

- Ghanem Romdhane, N., Djendoubi, N., Bonazzi, C., Kechaou, N., & Boudhrioua Mihoubi, N. (2016). Effect of combined air-drying-osmotic dehydration on kinetics of techno-functional properties, color and total phenol contents of lemon (Citrus limon. v. lunari) peels. International Journal of Food Engineering 12(6), 515-525. doi:10.1515/ijfe-2015-0252

- Grasso, S. (2020). Extruded snacks from industrial by-products: A review. Trends in Food Science & Technology 99, 284-294. doi:10.1016/j.tifs.2020.03.012

- Grzelak-Błaszczyk, K., Grzegorzewska, M., & Klewicki, R. (2021). Retention of flavonols in onions after osmotic dehydration. LWT 150, 112067. doi:10.1016/j.lwt.2021.112067

- Gutiérrez-Salomón, A. L., Hernández-Hernández, H. M., & Jaimez-Ordaz, J. (2021). Effect of osmotic and convective dehydration on the physicochemical, functional and sensory properties of Opuntia joconostle. Pädi Boletín Científico de Ciencias Básicas e Ingenierías del ICBI 9(17), 31-38. doi:10.29057/icbi.v9i17.6339

- Julca-Huarnizo, L., Vasquez-Torres, F., & Robles-Ruiz, J. (2019). Osmotic dehydration of mamey (Mammea americana L.) and its effect on the physicochemical and organoleptic characteristics. Functional Food Science and Technology Journal 1(1), 19-33. http://revistas.unprg.edu.pe/openjournal/index.php/cytaf/article/view/530

- Kaur, K., Kumar, S., & Alam, M. S. (2014). Air drying kinetics and quality characteristics of oyster mushroom (Pleurotus ostreatus) influenced by osmotic dehydration. Agricultural Engineering International: CIGR Journal 16(3), 214-222. Retrieved from https://cigrjournal.org/index.php/Ejounral/article/view/2831

- Kaushal, P., & Sharma, H. K. (2016). Osmo-convective dehydration kinetics of jackfruit (Artocarpus heterophyllus). Journal of the Saudi Society of Agricultural Sciences 15(2), 118-126. doi:10.1016/j.jssas.2014.08.001

- Keller, M., Ambrosio, E., de Oliveira, V. M., et al. (2020). Polyurethane foams synthesis with cassava waste for biodiesel removal from water bodies. Bioresource Technology Reports, 10, 100396. doi:10.1016/j.biteb.2020.100396

- Kowalski, S. J., & Szadzińska, J. (2014). Convective-intermittent drying of cherries preceded by ultrasonic assisted osmotic dehydration. Chemical Engineering and Processing: Process Intensification 82, 65-70. doi:10.1016/j.cep.2014.05.006

- Liu, L., Chen, J., Lim, P. E., & Wei, D. (2018). Enhanced single cell oil production by mixed culture of Chlorella pyrenoidosa and Rhodotorula glutinis using cassava bagasse hydrolysate as carbon source. Bioresource Technology 255, 140-148. doi:10.1016/j.biortech.2018.01.114

- Liu, Y., Wu, J., Chong, C., & Miao, S. (2014). Ultrasound assisted osmotic dehydration as pretreatment for hot-air drying of carrot. Food Science and Technology Research 20(1), 31-41. doi:10.3136/fstr.20.31

- Martínez, E. (2005). Frequent errors in the interpretation of the coefficient of linear determination. Escurialens Legal and Economic Yearbook, 315-332.

- Massolo, J. F., Ortiz, C., Concellon, A., & Vicente, A. (2020). Influence of the dehydration method on the quality of round zucchini snacks [Cucurbita maxima var. Zapallito (Carr.) Millán)]. Revista de la Facultad de Agronomía 119(1), 045. doi:10.24215/16699513e045

- Masztalerz, K., Lech, K., Wojdyło, A., Nowicka, P., Michalska-Ciechanowska, A., & Figiel, A. (2021). The impact of the osmotic dehydration process and its parameters on the mass transfer and quality of dried apples. Drying Technology 39(8), 1074-1086. doi:10.1080/07373937.2020.1741607

- Mendes, G. R. L., Freitas, C. H. de, Scaglioni, P. T., Schmidt, C. G., & Furlong, E. B. (2013). Condições para desidratação osmótica de laranjas e as propriedades funcionais do produto. Revista Brasileira de Engenharia Agrícola e Ambiental 17(11), 1210-1216. doi:10.1590/S1415-43662013001100012

- Moreira, R., Chenlo, F., Chaguri, L., & Vázquez, G. (2011). Air drying and colour characteristics of chestnuts pre-submitted to osmotic dehydration with sodium chloride. Food and Bioproducts Processing 89(2), 109-115. doi:10.1016/j.fbp.2010.03.013

- Mujic, I., Bavcon Kralj, M., Jokić, S., et al. (2014). Characterisation of volatiles in dried white varieties figs (Ficus carica L.). Journal of Food Science and Technology 51(9), 1837-1846. doi:10.1007/s13197-012-0740-x

- Muñiz-Becerá, S., Méndez-Lagunas, L. L., Rodríguez-Ramírez, J., Sandoval-Torres, S., López-Ortíz, A., & Barriada-Bernal, L. G. (2022). Modeling of solute transport inside plant tissue during osmotic dehydration of apple. Drying Technology 40(2), 387-400. doi:10.1080/07373937.2020.1798994

- Novales, A. (2010). Regression analysis. In: Department of Quantitative Economics. Complutense University of Madrid, Spain.

- Paternina, A., Salcedo, J., Contreras, K., & García, M. (2016). Characterization and desorption isotherm modeling of cassava bagasse (Manihot esculenta Crantz). In: Starch/Stärke 1-8. DOI:10.1002/star.201600020

- Polachini, T. C., Mulet, A., Cárcel, J. A., & Telis-Romero, J. (2019). Rheology of acid suspensions containing cassava bagasse: Effect of biomass loading, acid content and temperature. Powder Technology 354, 271-280. doi:10.1016/j.powtec.2019.05.086

- Romero de Armas, R., Alcívar Acosta, E., & Alpízar Muni, J. (2017). Cassava bran as a partial substitute for corn in the diet of fattening pigs. La Técnica: Revista de las Agrociencias 54. doi:10.33936/la técnica. v0i0.974

- Salcedo-Mendoza, M., Contreras-Lozano, J. G., García-López, K., & Fernández-Quintero, A. (2016). Modeling of the drying kinetics of cassava bran (Manihot esculenta Crantz). Revista Mexicana de Ingeniería Química 15(3), 883-891. http://rmiq.org/iqfvp/Pdfs/Vol.%2015,%20No.%203/Alim10/Alim10.html

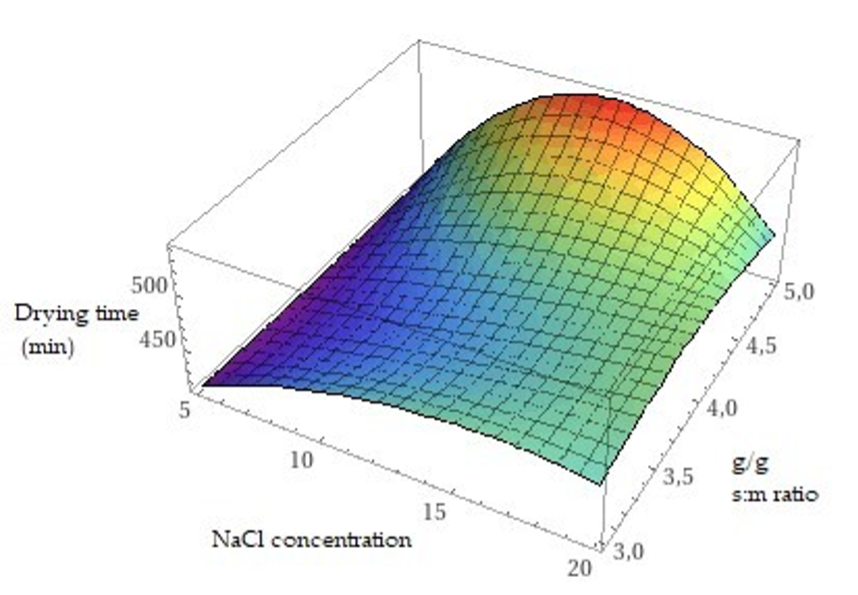

- Serpa-Fajardo, J., Narváez-Guerrero, D., Serpa-Padilla, C., Hernández-Ramos, E., & Fernández-Lambert, G. (2022). Assessment of parameters to apply osmotic dehydration as pretreatment for improving the efficiency of convective drying of Cassava bagasse. Applied Sciences 12, 12101. https://doi.org/10.3390/app122312101

- Sharma, M., & Dash, K. K. (2019). Effect of ultrasonic vacuum pretreatment on mass transfer kinetics during osmotic dehydration of black jamun fruit. Ultrasonics Sonochemistry 58, 104693. doi:10.1016/j.ultsonch.2019.104693

- Sutar, P. P., & Prasad, S. (2011). Optimization of osmotic dehydration of carrots under atmospheric and pulsed microwave vacuum conditions. Drying Technology 29(3), 371-380. doi:10.1080/07373937.2010.497955

- Taşova, M., Polatcı, H., & Gökdoğan, O. (2022). Effect of osmotic dehydration pre-treatments on physicochemical and energy parameters of Kosia (Nashi) pear slices dried in a convective oven. Journal of Food Process Preservation. doi:10.1111/jfpp.16945

- Thuy, N. M., Tham, N. T., Minh, V. Q., Vu, P. T., & Tai, N. van. (2021). Evaluation of water loss and solute uptake during osmotic treatment of white radishes (Raphanus sativus L.) in salt-sucrose solution. Plant Science Today. doi:10.14719/pst.1422

- Thuy, N. M., Giau, T. N., Tai, N.V., Minh, V.Q. (2023). Drying kinetics and mathematical modeling of dried macaroni supplemented with Gac aril. Revista Mexicana de Ingeniería Química 22 (3), Alim23103. https://doi.org/10.24275/rmiq/Alim23103

- Vargas Corredor, Y. A., & Pérez Pérez, L. I. (2018). Use of agro-industrial waste to improve the quality of the environment. Revista Facultad de Ciencias Básicas 59-72. doi:10.18359/rfcb.3108

- WolframAlpha LLC. (2009). URL: www.wolframalpha.com

|