|

|

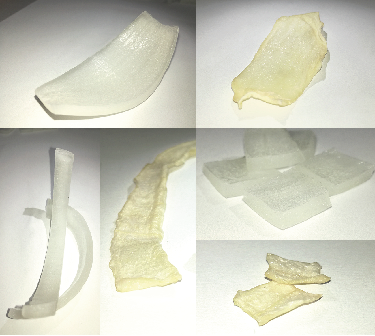

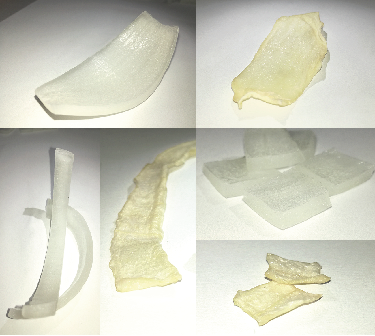

The waste of food in México was over 16.5 tons’ millions in 2009. In the case of the onion, it was 250,352.61 tons. This research proposes a methodology to avail the wasted onion through vibrofluidized bed drying (VBD). The air-drying temperature, the charge of the material into the dryer and the geometry of the cut was analyzed with respect to the effective diffusion coefficient (Def) [m2s-1], the value of residual pungency (mmol piruvate g-1) and production cost ($/kg-1). The percentage of retention for initial pungency was 42-52, 50-56 and 56-72 in dried onion at 60, 70 and 80 °C respectively. The greater values were for onions segments geometry. There was not difference on Def for the bulk of material for any geometry, however the Def value in onions segments was greater than square or middle slices geometry. The activation energy (Ea), increased with respect to the charge of material into the dryer. The averages of Ea were no significant difference respect to the geometry but were different respect to the relation of material bulk 0.5 and 1.5. The lowest production cost was obtained in rectangular prisms and half slices with 40.46 $ kg-1 onion.

Keywords: valorization, waste onion, drying, vibro-fluidized bed.

|

|

|