|

|

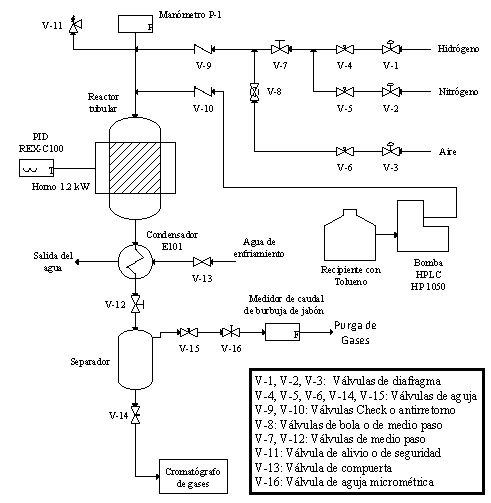

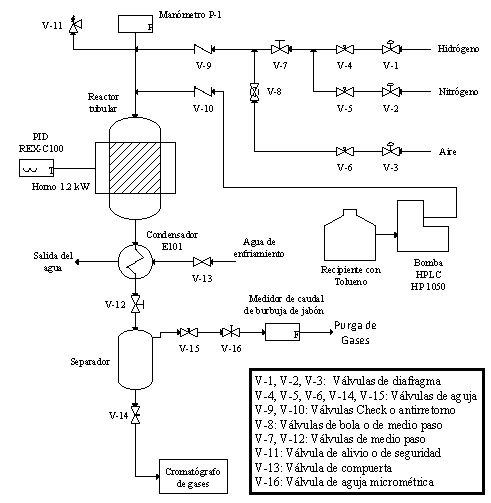

In this work, solid catalysts containing metals used in petroleum refinery and their potential regeneration were characterized and evaluated. The catalysts studied consist of metals supported on γ-Al2O3: Pt/Al2O3 and Pd-Rh/Al2O3. In the physicochemical characterization was determined the BET surface area, Thermal analysis TGA-DSC, XRF and metallic dispersion. The catalytic activity of the solids was determined in a laboratory-scale plant for evaluation of catalysts, with a fixed-bed tubular reactor using as model reaction the hydrogenation of toluene at WHSV= 2 h-1, T= 498 K, 8:1 molar ratio of H2-toluene, hydrogen pressure = 724 kPa. The products analysis was carried out in a GC-MS, with methyl ciclohexane as an only product. The standard catalyst (Cat-REF) 0.5% Pt / Al2O3, was evaluated in this reaction and then coked, achieving 97% conversion before and after regeneration. Several methodologies were carried out to regenerate the deactivated industrial catalysts containing sulphur. These catalysts were characterized by the mentioned techniques and catalytically evaluated in the model reaction. The results show that the sulfur content of Pd-Rh/Al2O3 catalyst was reduced from 7420 ppm to 370 ppm, thus 95% of sulfur was removed, and however this catalyst exhibits a toluene conversion of less than 1%.

Keywords: poisoning, TGA-DSC, catalyst regeneration, fixed-bed tubular reactor, toluene hydrogenation, WHSV.

|

|

|