|

|

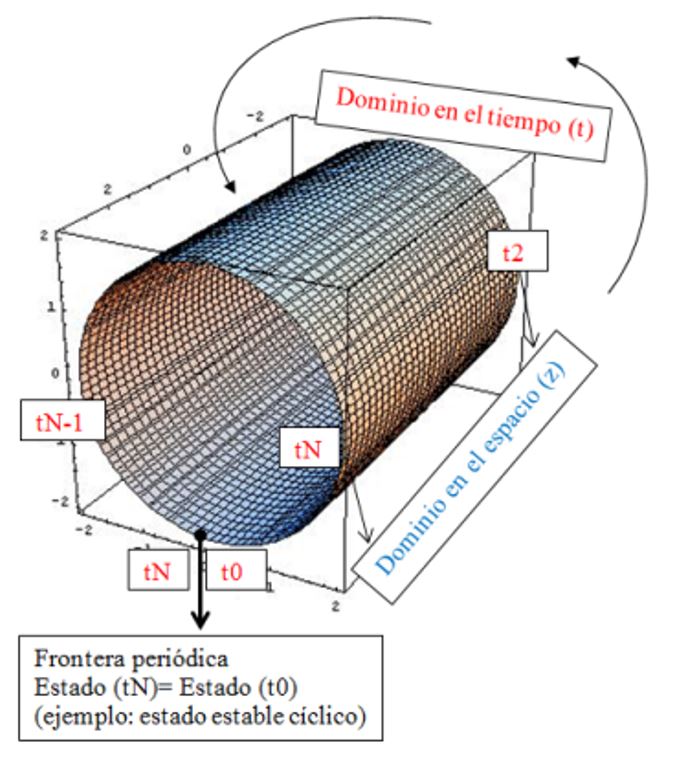

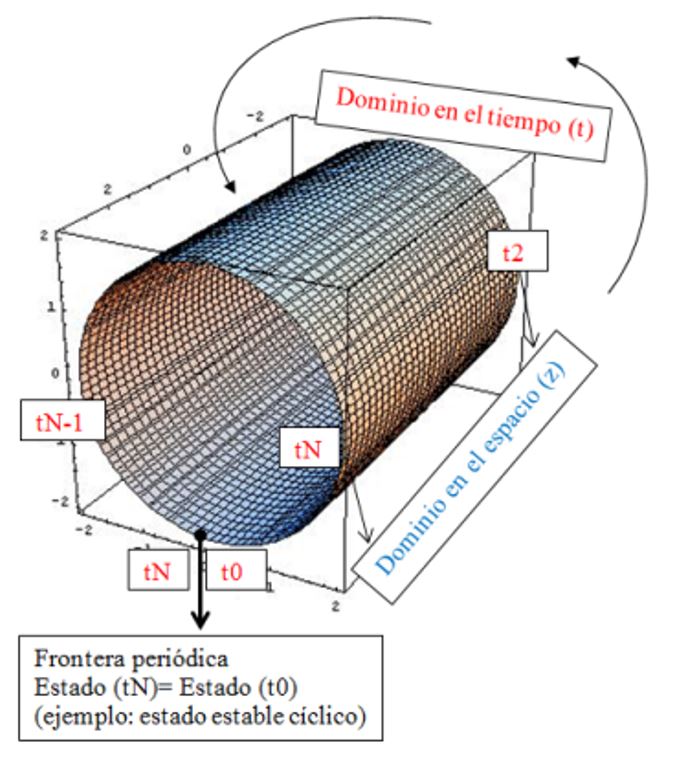

Adsorption with molecular sieves using pressure oscillation to adsorb the water molecule is one of the new processes that exist to produce dehydrated ethanol

complying with international purity standards (99\% ethanol). In this study, the pressure swing adsorption process (PSA) was simulated and controlled using

the Aspen Adsorption and Simulink simulator. To define the primary control loop, a sensitivity analysis was carried out that allowed to know the effects of

some variables (inputs) on the purity of the obtained ethanol (output), this helped to identify a reduced model (Hammerstein-Wiener) using the input and

output data of the rigorous PSA model. Subsequently the optimal predictive controller (Optimal MPC) design was made using the reduced model.

To validate the robustness and stability of the controller, it was applied to the rigorous PSA model, testing it in simulations before changes (perturbations) of

temperature, purge times and changes in the feed composition. The most relevant results of this work give rise to the fact that when applying a controller

and defining a variable continues along all the steps of the process, the control quickly manages to maintain the desired purity in a smaller number of cycles

before different changes.

Keywords: Brownian motion, Ito's calculus, Optimal control, Stochastic processes, White noise.

|

|

|