|

|

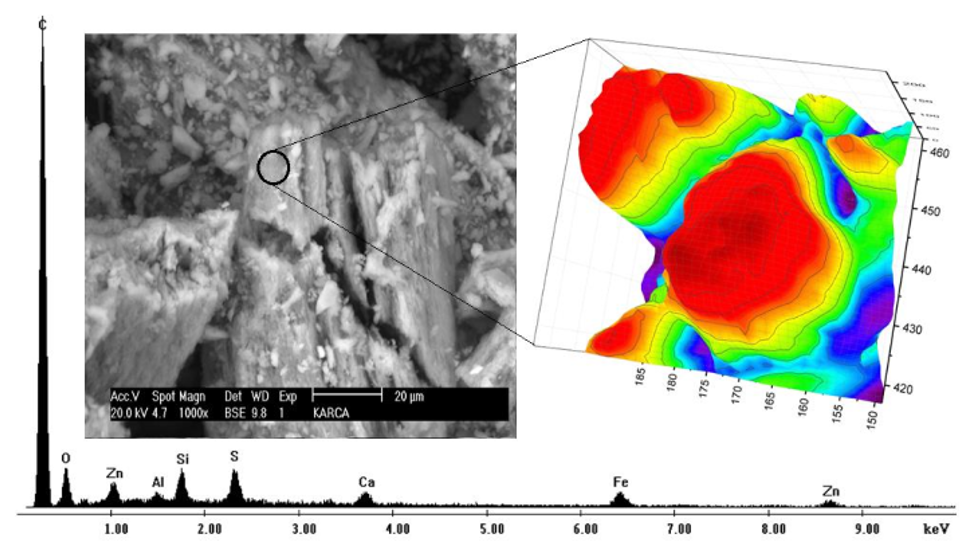

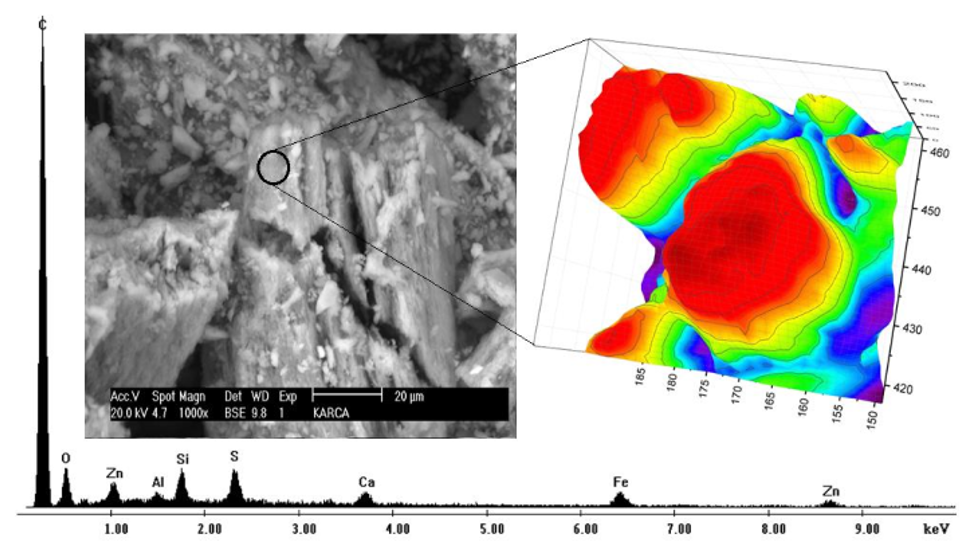

Esterification of oleic acid was carried out to obtain methyl esters at temperatures below the critical point of methanol in the presence of sulfonated carbon. That was obtained by pyrolysis from tire rubber and use as catalytic support after sulfonated. The sulfonated carbonaceous material in the laboratory was analyzed by spectroscopy and microscopic techniques: IR spectroscopy, X-ray diffractometry, programmed desorption at a temperature (TG-DTG), X-ray photoelectron spectroscopy and scanning electron microscopy. The physicochemical properties of catalyst favor high performance in the production of biodiesel from oleic acid, are easily separated from the liquid mixture at the end of the reaction. At the temperature of 200 °C, with a reaction time of 20 min and a catalyst amount of 0.03% by weight, was the optimal experimental conditions for the esterification of oleic acid with methanol, giving a conversion of 97.9% of free fatty acids according to the response surface method. The Box-Behnken experiments were applied in order to evaluate the effects of the production parameters of biodiesel and find out the optimal conditions to obtain the maximum yield. Interestingly, stable catalytic activity in several reaction cycles was found.

Keywords: Biodiesel production; solid acid catalyst; sulfonation treatment; Box-Behnken method; reaction cycles.

|

|

|