|

|

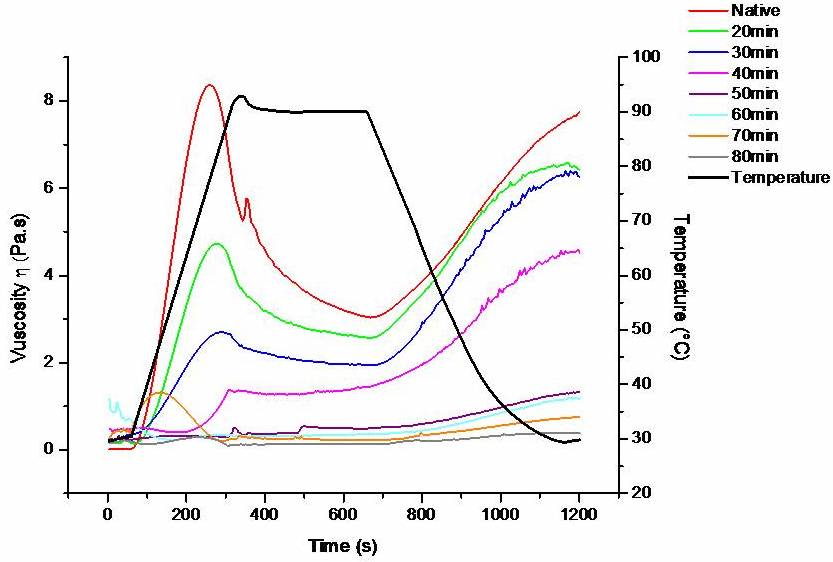

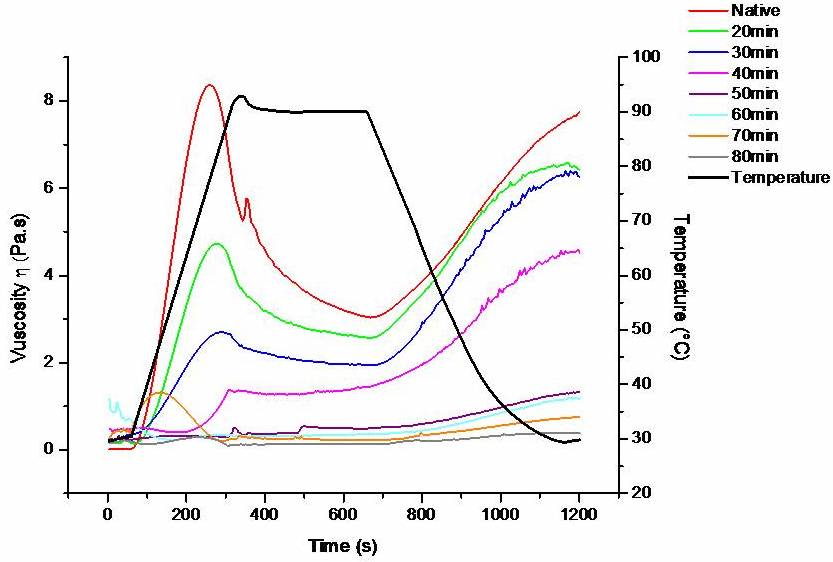

In the present work, time-variable modeling of high-energy mechanical grinding (0, 20, 30, 40, 50, 60, 70, and 80 min), was carried out to obtain the best grinding conditions process for obtaining modified starches with applications as wall materials with favorable viscosity and particle size characteristics for the nano-encapsulation of bioactive compounds by means of nano-spray drying. The pasting profile was affected by the different mechanical grinding times, since the maximum viscosity (95 ºC) decreased as the grinding time increased, but this was not the case in the cooling stage (30 ºC) since at times of 30 and 40 min the viscosity was more significant than the maximum viscosity. The modified starches showed larger particle sizes compared to their native counterpart, indicating the formation of agglomerations. The model presents an adequate fit with respect to the experimental data and the feasible and infeasible conditions of this process are represented.

Keywords: Nano-spray,

Starch modified,

Wall materials,

Nano-encapsulation,

Modeling.

|

|

|