- Ahumada C.D., Hinojosa- Palafox J.F., Maytorena V.M., Pérez-Rábago, C. (2022). Computational study of biomass fast pyrolysis in a fluidized bed reactor. Revista Mexicana de Ingeniería Química Vol. 21, No. 2. ISSN:1665-2738. issn-e: 2395-8472

- https://doi.org/10.24275/rmiq/Cat2744

- Antonangelo, J.A., Zhang, H., Sun, X. Kumar A., Physicochemical properties and morphology of biochars as affected by feedstock sources and pyrolysis temperatures. Biochar 1, 325–336 (2019). https://doi.org/10.1007/s42773-019-00028-z

- Honorato-Salazar, J.A., Sadhukhan, J. (2020). Annual biomass variation of agriculture crops and forestry residues, and seasonality of crop residues for energy production in Mexico. Food and Biomass Processing 119, 1-19. https://doi.org/10.1016/j.fbp.2019.10.005.

- Iwuozor, K.O., Emenike, E.Ch., Ighalo, J.O., Omoaruke, F.O., Omuku, P.E., Adeniyi, A. G. (2022). Cleaner Materials 6 100162. https://doi.org/10.1016/j.clema.2022.100162

- Karp, S.G., Woiciechowski, A.L., Soccol V.T., Soccol R. (2013). Pretreatment strategies for delignification of sugarcane bagasse: A review. Brazilian Archives of Biology and Technology 56, 679-689. https://doi.org/10.1590/S1516-89132013000400019

- Kumar, M., Upadhyay, S.N., Mishra, P.K. (2022). Pyrolysis of sugarcane (Saccharum officinarum L.) Leaves and Characterization Products, ACS Omega, 7, 28052-28064. https://doi.org/10.1021/acsomega.2c02076

- Marín Apolo, Y.C., Vega Iñiguez, M.E., Ochoa-Correa D. (2025). Aprovechamiento de residuos agrícolas para producción de electricidad en Latinoamérica: Revisión literaria de casos exitosos en México, Colombia y Brasil. InGenio Journal 8(1) 46-68. https://doi.org/10.18779/ingenio.v8il.901

- Parihar, M.F., Kamil, M., Goyal, H.B., Gupta, A.K., Bhatnagar, A.K. (2007). An experimental study on pyrolysis of biomass. Trans I Chem. E., Part B. Process Safety and Environmental Protection 85, B5, 458-465. https://doi.org/10.1205/psep07035

- Rambhatla, N., Panicker, T., Mishra, R.K., Manjeshwar, S.K., Sharma, A. (2025). Biomass pyrolysis for biochar production: Study of kinetics parameters and effect of temperature on biochar yield its physicochemical properties. Results in engineering 25, 103679 1-12. https://doi.org/10.1016/j.rineng.2024.103679

- Romero-Bonilla, H. I., Jaramillo-Guanolique, A., Zambrano, C., Rios-Hidalgo, M., Solano-Maza, L., Choez-Tobo, C. (2025). Cocoa shell biochars for sustainable biodiesel production in Ecuador. Revista Mexicana de Ingeniería Química 24, No. 1, IE24221. https://doi.org/10.24275/rmiq/IE24221 ISSN:1665-2738, issn-e: 2395-8472

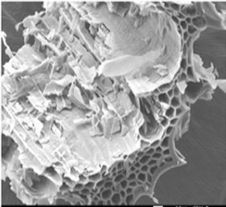

- Sánchez Castillo, O., Vizcarra-Mendoza, M.G., Martínez Vera, C., Gómez Torres, S.A., Rojas García, E. (2025). Producción de biochar a partir de la pirólisis de bagazo de caña de azúcar. Avances en IQ 4(1), AMB 343-AMB348. ISSN: 2683-2925.

- Tillman, D.A. (1978). Fuels and Combustion Handbook. Mc Graw-Hill, NY, p.65.

- Toscano Miranda, N., Lopes Motta, I., Maciel Filho, R., Wolf Maciel, M.R. (2021). Sugarcane bagasse pyrolysis: A review of operating conditions and products properties. Renew. Sustain. Energy Rev. 149, 111394. https://doi.org/10.1016/j.rser.2021.111394

- van Krevelen, D. W. (1950). Graphical-statistical method for the study of structure and reaction processes of coal. Fuel 29, 269-284.

- Weber, K., Quicker, P. (2018). Properties of biochar. Fuel 217, 240-261. https://doi.org/10.1016/j.fuel.2017.12.054

- Xu, J., Liu, J., Ling, P., Zhang, X., Xu, K., He, L., Wang, Y., Su, S., Hu, S., Xiang, J. (2020). Raman spectroscopy of biochar from the pyrolysis of three typical Chinese biomasses: A novel method for rapidly evaluating the biochar property. Results in Energy 202(1-10) 117644. https://doi.org/10.1016/j.energy.2020.117644

- Zafranet (2025). Available at: https://www.zafranet.com/noticias/zafra-2024-25-produccion-de-azucar-acumulada-supera-los-4-6-millones-de-toneladas/ Accessed: June 24, 2025.

|