- Adebayo Albert, O., A. Adebayo Matthew, F. Olasehinde Emmanuel and O. Ojo Olayemi (2021). Leaching Kinetics of Lead from Galena Using Hydrogen Peroxide and Trichloroacetic Acid. Journal of Hazardous, Toxic, and Radioactive Waste 25(3): 04021010. DOI: 10.1061/(ASCE)HZ.2153-5515.0000608

- Adebayo, A. O. and E. F. Olasehinde (2015). Leaching kinetics of lead from galena with acidified hydrogen peroxide and sodium chloride solution. Mineral Processing and Extractive Metallurgy 124(3): 137-142. DOI: 10.1179/1743285515Y.0000000001

- Arwidsson, Z., K. Elgh-Dalgren, T. von Kronhelm, R. Sjöberg, B. Allard and P. van Hees (2010). Remediation of heavy metal contaminated soil washing residues with amino polycarboxylic acids. Journal of Hazardous Materials 173(1): 697-704. DOI: https://doi.org/10.1016/j.jhazmat.2009.08.141

- Cheikh, M., J. P. Magnin, N. Gondrexon, J. Willison and A. Hassen (2010). Zinc and lead leaching from contaminated industrial waste sludges using coupled processes. Environmental Technology 31(14): 1577-1585. DOI: 10.1080/09593331003801548

- Chen, C.-S., Y.-J. Shih and Y.-H. Huang (2016). Recovery of lead from smelting fly ash of waste lead-acid battery by leaching and electrowinning. Waste Management 52: 212-220. DOI: https://doi.org/10.1016/j.wasman.2016.03.056

- Clesceri, L. S., A. E. Greenberg and R. R. Trussell (1999). Standard Methods for the Examination of Water and Wastewater, American Public Health Association

- Druschel, G. K., R. J. Hamers and J. F. Banfield (2003). Kinetics and mechanism of polythionate oxidation to sulfate at low pH by O2 and Fe3+. Geochimica et Cosmochimica Acta 67(23): 4457-4469. DOI: https://doi.org/10.1016/S0016-7037(03)00388-0

- Fan, Y., Y. Liu, L. Niu, W. Zhang and T.-a. Zhang (2021). High purity metal lead recovery from zinc direct leaching residue via chloride leaching and direct electrolysis. Separation and Purification Technology 263: 118329. DOI: https://doi.org/10.1016/j.seppur.2021.118329

- Hewitt, D. M., P. L. Breuer, M. I. Jeffrey and F. Naim (2009). Mechanisms of sulfide ion oxidation during cyanidation. Part II: Surface catalysis by pyrite. Minerals Engineering 22(13): 1166-1172

- HSC Chemistry v. 6.12. Outotec Research. Oy, Pori, Finland.

- Hsieh, Y. H. and C. P. Huang (1989). The dissolution of PbS(s) in dilute aqueous solutions. Journal of Colloid and Interface Science 131(2): 537-549. DOI: https://doi.org/10.1016/0021-9797(89)90196-3

- Ichlas, Z. T., R. A. Rustandi and M. Z. Mubarok (2020). Selective nitric acid leaching for recycling of lead-bearing solder dross. Journal of Cleaner Production 264: 121675. DOI: https://doi.org/10.1016/j.jclepro.2020.121675

- Javadi Nooshabadi, A. and K. H. Rao (2016). Complex sulphide ore flotation: Effect of depressants addition during grinding on H2O2 formation and its influence on flotation. International Journal of Mineral Processing 157: 89-97. DOI: https://doi.org/10.1016/j.minpro.2016.09.007

- John, J. J., V. De Houwer, D. Van Mechelen and T. Van Gerven (2020). Effect of ultrasound on leaching of lead from landfilled metallurgical residues. Ultrasonics Sonochemistry 69: 105239. DOI: https://doi.org/10.1016/j.ultsonch.2020.105239

- Kilroy, W. P. (1979). A revised method, and errors in the determination of thiosulphate by the Wollak method. Talanta 26(2): 111-115. DOI: https://doi.org/10.1016/0039-9140(79)80226-X

- Kim, E., L. Horckmans, J. Spooren, K. C. Vrancken, M. Quaghebeur and K. Broos (2017). Selective leaching of Pb, Cu, Ni and Zn from secondary lead smelting residues. Hydrometallurgy 169: 372-381. DOI: https://doi.org/10.1016/j.hydromet.2017.02.027

- Kobayashi, M., J. E. Dutrizac and J. M. Toguri (1990). A Critical Review of the Ferric Chloride Leaching of Galena. Canadian Metallurgical Quarterly 29(3): 201-211. DOI: 10.1179/cmq.1990.29.3.201

- Kohr, W. (1997). Method for rendering refractory sulfide ores more susceptible to biooxidation. Minerals Engineering 10(9): 1043-1043. DOI: Doi: 10.1016/s0892-6875(97)82912-3

- Kumar, R. V. (2017). A low-cost green technology for recovering lead paste and lead-alloy grid materials for spent lead acid batteries. Mineral Processing and Extractive Metallurgy 126(1-2): 89-93. DOI: 10.1080/03719553.2016.1263783

- Miura, Y., H. Kitamura and T. Koh (1991). Spectrophotometric determination of micro amounts of tetrathionate via its oxidation with permanganate. Microchimica Acta 103(5): 235-243. DOI: 10.1007/BF01243260

- Nikkhou, F., F. Xia, A. P. Deditius and X. Yao (2020). Formation mechanisms of surface passivating phases and their impact on the kinetics of galena leaching in ferric chloride, ferric perchlorate, and ferric nitrate solutions. Hydrometallurgy 197: 105468. DOI: https://doi.org/10.1016/j.hydromet.2020.105468

- NIST (2004). Critical Stability Constants, National Institute for Standards and Technology, database 46.8

- O'Connor, D., D. Hou, J. Ye, Y. Zhang, Y. S. Ok, Y. Song, F. Coulon, T. Peng and L. Tian (2018). Lead-based paint remains a major public health concern: A critical review of global production, trade, use, exposure, health risk, and implications. Environment International 121: 85-101. DOI: https://doi.org/10.1016/j.envint.2018.08.052

- Oh, J. K., J. Y. Lee, H. Y. Lee, S. G. Kim, C. Han and J. K. Shin (1999). Leaching of Lead Sulfide with Nitric Acid. Geosystem Engineering 2(1): 1-6. DOI: 10.1080/12269328.1999.10541133

- Osasona, I., O. E. Oke and A. O. Adebayo (2021). Direct Leaching of Lead from Galena Using Acetic Acid in Iron(III) Chloride. Journal of Hazardous, Toxic, and Radioactive Waste 25(3)

- Puigdomenech, I. (2004). Make equilibrium diagrams using sophisticated algorithms (MEDUSA), inorganic chemistry. Royal Institute of Technology. Stockholm, Sweden

- Rammah, Y. S., K. A. Mahmoud, M. I. Sayyed, F. I. El-Agawany and R. El-Mallawany (2020). Novel vanadyl lead-phosphate glasses: P2O5–PbO–ZnONa2O–V2O5: Synthesis, optical, physical and gamma photon attenuation properties. Journal of Non-Crystalline Solids 534: 119944. DOI: https://doi.org/10.1016/j.jnoncrysol.2020.119944

- Rolia, E. and F. Barbeau (1980). Estimation of individual thio-salts and sulphate in flotation mill solutions.Talanta 27(7): 596-598. DOI: https://doi.org/10.1016/0039-9140(80)80187-1

- Ruiz-Vela J.I., E.E. Rodríguez-Vázquez, Y. Gudiño-Pérez, R. Sánchez-Ramírez, J.J. Montes-Rodríguez (2023). Effect of complexing/buffering agent on the characteristics of a high phosphorous electroless nickel coating. Revista Mexicana de Ingeniería Química 22(2): 1-10. DOI: 10.24275/rmiq/Proc2331

- Segura-Bailón, B. and G. Lapidus-Lavine (2023). Importance of chemical pretreatment for base metals remotion and it effect on the selective extraction of gold from Printed Circuits Boards (PCBs).Revista Mexicana de Ingeniería Química 22: 1-17. DOI: 10.24275/rmiq/IA2335

- Seyed Ghasemi, S. M. and A. Azizi (2018). Alkaline leaching of lead and zinc by sodium hydroxide: kinetics modeling. Journal of Materials Research and Technology 7(2): 118-125. DOI: https://doi.org/10.1016/j.jmrt.2017.03.005

- Smaniotto, A., A. Antunes, I. d. N. Filho, L. D. Venquiaruto, D. de Oliveira, A. Mossi, M. Di Luccio, H. Treichel and R. Dallago (2009). Qualitative lead extraction from recycled lead–acid batteries slag. Journal of Hazardous Materials 172(2): 1677-1680. DOI: https://doi.org/10.1016/j.jhazmat.2009.07.026

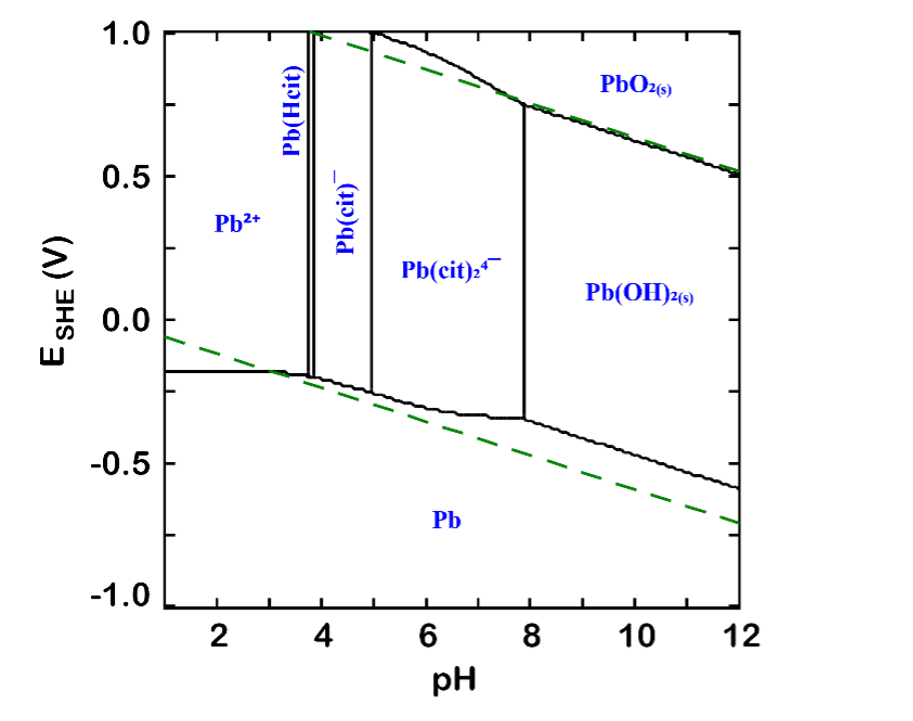

- Solís-Marcial, O. J., A. Nájera-Bastida, A. Talavera-López, B. Serrano Rosales, J. A. Hernandez and R. Zarate-Gutiérrez (2022). Thermodynamic Study of Leaching Conditions of Galena with Citrate Ions and Hydrogen Peroxide as Oxidizing Agent. Materials (1996-1944) 15(21): 7704. DOI: 10.3390/ma15217704

- Sonmez, M. S. and R. V. Kumar (2009a). Leaching of waste battery paste components. Part 1: Lead citrate synthesis from PbO and PbO2. Hydrometallurgy 95(1): 53-60. DOI: https://doi.org/10.1016/j.hydromet.2008.04.012

- Sonmez, M. S. and R. V. Kumar (2009b). Leaching of waste battery paste components. Part 2: Leaching and desulphurisation of PbSO4 by citric acid and sodium citrate solution. Hydrometallurgy 95(1): 82-86. DOI: https://doi.org/10.1016/j.hydromet.2008.04.019

- Takagi, J. and K. Ishigure (1985). Thermal Decomposition of Hydrogen Peroxide and Its Effect on Reactor Water Monitoring of Boiling Water Reactors. Nuclear Science and Engineering 89(2): 177-186. DOI: 10.13182/NSE85-A18191

- Tang, L., C. Tang, J. Xiao, P. Zeng, M. Tang, Z. Wang and Z. Zhang (2019). A cleaner process for lead recovery from lead-containing hazardous solid waste and zinc leaching residue via reducing-matting smelting. Journal of Cleaner Production 241: 118328. DOI: https://doi.org/10.1016/j.jclepro.2019.118328

- Torres, R. and G. T. Lapidus (2020). Base metal citrate pretreatment of complex ores to improve gold and silver leaching with thiourea.Hydrometallurgy 197: 105461. DOI: https://doi.org/10.1016/j.hydromet.2020.105461

- Torres, R., B. Segura-Bailón and G. T. Lapidus (2018). Effect of temperature on copper, iron and lead leaching from e-waste using citrate solutions. Waste Management 71: 420-425. DOI: https://doi.org/10.1016/j.wasman.2017.10.029

- USGS (2023). Mineral Commodity Summary USGS Series definitions- USGS Publications Warehouse.

- Villa, L. C., W. Saldarriaga Agudelo and N. R. Rojas (2018). Estudio termodinámico de la lixiviación de plomo reciclado con citrato de sodio. Ciencia en Desarrollo 9(2): 119-126. DOI: 10.19053/01217488.v9.n2.2018.7262

- Wang, L., W.-n. Mu, H.-t. Shen, S.-m. Liu and Y.-c. Zhai (2015). Leaching of lead from zinc leach residue in acidic calcium chloride aqueous solution. International Journal of Minerals, Metallurgy, and Materials 22(5): 460-466. DOI: 10.1007/s12613-015-1094-y

- Wang, S., Z. Fang, Y. Wang and Y. Chen (2003). Electrogenerative leaching of galena with ferric chloride. Minerals Engineering 16(9): 869. DOI: 10.1016/S0892-6875(03)00205-X

- Wasserlauf, M. and D. E. Dutrizac (1982). The Chemistry, Generation and Treatment of Thiosalts in Milling Effluents: A Non-critical Summary of Canmet Investigations 1975-1982, Canada Centre for Mineral and Energy Technology

- Xie, H., X. Xiao, Z. Guo and S. Li (2022). One-stage ultrasonic-assisted calcium chloride leaching of lead from zinc leaching residue. Chemical Engineering and Processing - Process Intensification 176: 108941. DOI: https://doi.org/10.1016/j.cep.2022.108941

- Zárate-Gutiérrez, R. and G. T. Lapidus (2014). Anglesite (PbSO4) leaching in citrate solutions. Hydrometallurgy 144-145: 124-128. DOI: https://doi.org/10.1016/j.hydromet.2014.02.003

- Zárate-Gutiérrez, R., L. Gregorio-Vázquez and G. T. Lapidus (2015). Selective leaching of lead from a lead–silver–zinc concentrate with hydrogen peroxide in citrate solutions. Canadian Metallurgical Quarterly 54(3): 305-309. DOI: 10.1179/1879139515Y.0000000020

- Zhang, P.-y., L.-m. Ou, L.-m. Zeng, W.-g. Zhou and H.-t. Fu (2019). MLA-based sphalerite flotation optimization: Two-stage roughing. Powder Technology 343: 586-594. DOI: https://doi.org/10.1016/j.powtec.2018.11.085

|